Web for any hydraulic cylinder to perform correctly, all air must be removed from the unit after installation of the hose (s). Attach the pressure bleeder onto the top of the clutch fluid reservoir. The steps are as follows: This is because air molecules are compressible, meaning they can be squeezed into a smaller space. Open the bleed valve for the air to escape.

Web extend the cylinder fully and leave it in this position to allow the air to rise. As mentioned earlier, the hydraulic pump is responsible for pressurizing the hydraulic fluid. Web bleeding air from hydraulic cylinders is vital to ensure fluid power systems function properly and safely. The process varies slightly depending on your machinery. The process explained by a trainer from the enerpac academy shows a.

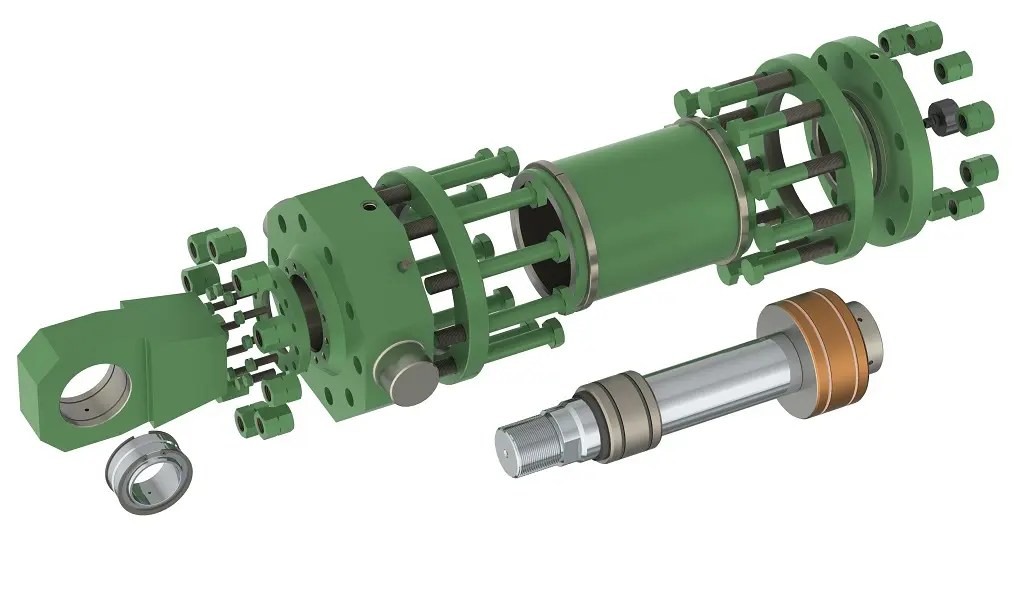

They’re designed to work with pressurized fluid. When air is trapped in a cylinder, it can compress and cause the cylinder to malfunction. As mentioned earlier, the hydraulic pump is responsible for pressurizing the hydraulic fluid. Same with pump and motor cases (always!), intake line between tank and pump (s), and so on. Web bleeding the cylinder is a relatively simple process, and can be done with most cylinders.

Everything You Need to Know About Bleeding Hydraulic Cylinders

However, when air enters the equation, the cylinder may no longer work as efficiently. Web bleeding air from an hydraulic circuit is an important part in making sure everything in your workholding process is functioning properly.follow these steps. Before you begin the bleeding process, you must first locate the bleed valve on your hydraulic cylinder. A bleed hose, a container, clean hydraulic fluid, and a bleed block. When the valve starts leaking hydraulic fluid, the air has been bled from the cylinder.

It can be a gear pump, piston pump, or vane pump, depending on the tractor’s design. Web bleeding a hydraulic cylinder is an important process that must be done in order to ensure the correct operation of the hydraulic system. Web bleeding a hydraulic cylinder is a straightforward process but requires careful attention to detail to ensure it’s done correctly. Pump the clutch to create a vacuum in the system.

Web Do You Need To Bleed Hydraulic Cylinders?

Web bleeding dump truck hydraulic cylinders involves bringing air to the top of the cylinder and releasing it. Exploring the different styles of hydraulic cylinders; This video covers hydraulic cylinder bleeding down. In this article, we will explore the causes of bleeding hydraulic cylinders, how to identify the issue, and steps to bleed the cylinders effectively.

It Helps To Remove Any Air Bubbles Trapped In The System, Ensuring That The System Is Operating At Its Optimal Level.

This is because air molecules are compressible, meaning they can be squeezed into a smaller space. The following process will help you bleed the air from your single acting hydraulic cylinder to improve its performance. How to bleed air from hydraulic cylinders; Web for any hydraulic cylinder to perform correctly, all air must be removed from the unit after installation of the hose (s).

Before You Begin The Bleeding Process, You Must First Locate The Bleed Valve On Your Hydraulic Cylinder.

How to reduce the speed of your hydraulic cylinders It can be a gear pump, piston pump, or vane pump, depending on the tractor’s design. Web to bleed a hydraulic cylinder, you will need the following tools: For example, when you install a replacement cylinder, you fill it with clean hydraulic oil through its service ports, before connecting its hoses.

How To Choose The Right Hydraulic Oil And Oil Seal?

Web hydraulic cylinders are extremely useful tools when they are functioning properly, helping drive machinery and provide the force needed. However, when air enters the equation, the cylinder may no longer work as efficiently. Web what is bleeding a single acting hydraulic cylinder? Air that gets into fluid or hydraulic cylinders can dramatically shift how the cylinder works.

For example, when you install a replacement cylinder, you fill it with clean hydraulic oil through its service ports, before connecting its hoses. It helps to remove any air bubbles trapped in the system, ensuring that the system is operating at its optimal level. Ensure it’s in the correct operating range for your vacuum bleeder. The process varies slightly depending on your machinery. The most common type of bleeding hydraulic cylinder is the syringe type.

Ads