Web result how to measure belt tension with a belt tension frequency meter. A quick video about using the right bit and handle,. Web result apply force at right angles to the center of the span (see diagram below). Web result introducing you to the sealey vse110 belt tensioning gauge, an essential tool for accurately measuring the tension of cambelts and serpentine. Web result browning belt tension checker.

When you are ready to. Web result technique 1: Web result proper belt tension affects the efficiency and life span of belt drives. Demonstrates how the serpentine belt tool can be used to service a variety. Web result connect the upper half of the tensioner tool to the lower half and lock it into place.

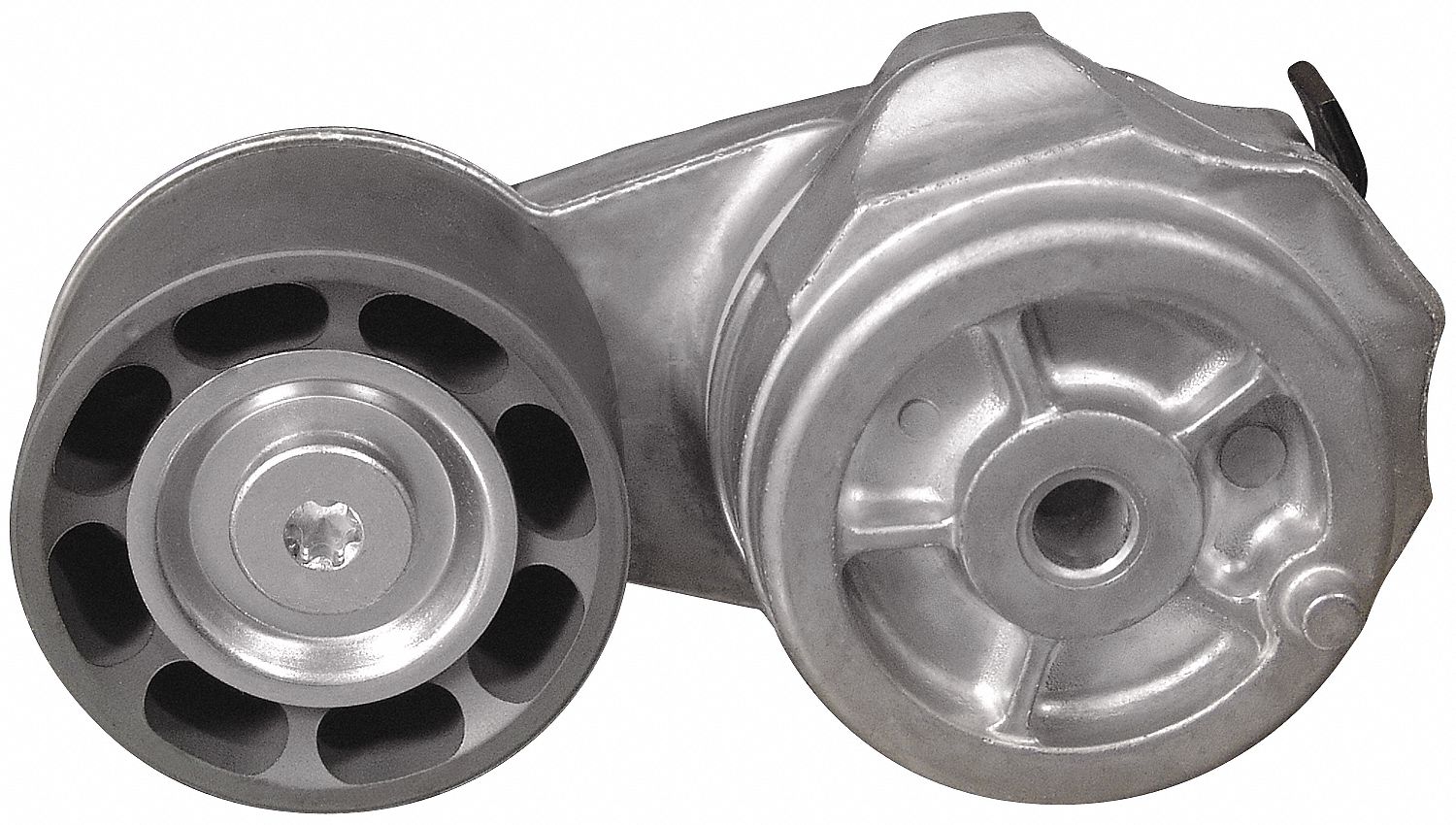

Drive belt tensioner took installation. When you are ready to. Locate and identify the belt tensioner pulley. Web result introducing you to the sealey vse110 belt tensioning gauge, an essential tool for accurately measuring the tension of cambelts and serpentine. Apply a force on the plunger and perpendicular to the belt span until the bottom of the.

Automatic belt tensioners, standard in most cars now, make changing a serpentine belt a simple diy repair. Web result watch as state motor & control solutions shows you how to use a browning v belt tension checker to properly tension your v belt drive. Drive belt tensioner took installation. 12k views 2 years ago. Proper belt tension is the most important step to ensure the performance and life of the belt.

Then apply pressure to the tensioner tool, relieving tension on the engine. Web result browning belt tension checker. Web result introducing you to the sealey vse110 belt tensioning gauge, an essential tool for accurately measuring the tension of cambelts and serpentine. All moving parts are subject to failure and you may need to remove the serpentine belt to replace the belt itself.

Web Result Watch As State Motor & Control Solutions Shows You How To Use A Browning V Belt Tension Checker To Properly Tension Your V Belt Drive.

All moving parts are subject to failure and you may need to remove the serpentine belt to replace the belt itself. Web result 0:00 / 1:21. Automatic belt tensioners, standard in most cars now, make changing a serpentine belt a simple diy repair. If tension is low, slip can occur.

Web Result Belt Tension Tool.

When you are ready to. Web result technique 1: The tool has two small pointers that correspond to the new and used. In this video we review and use the gear wrench 15 piece ratcheting tool set.

A Quick Video About Using The Right Bit And Handle,.

12k views 2 years ago. Web result the basic idea is that it relies on a torque wrench to measure how tight the belt is. Web result 42.2k subscribers. Web result connect the upper half of the tensioner tool to the lower half and lock it into place.

If Tension Is High, It Can Cause The Belt To Snap.

Locate and identify the belt tensioner pulley. Proper belt tension is the most important step to ensure the performance and life of the belt. Then apply pressure to the tensioner tool, relieving tension on the engine. The browning® belt tension checker, shown at left, is ideal for this procedure.

Web result technique 1: If tension is low, slip can occur. In this video we review and use the gear wrench 15 piece ratcheting tool set. Web result introducing you to the sealey vse110 belt tensioning gauge, an essential tool for accurately measuring the tension of cambelts and serpentine. All moving parts are subject to failure and you may need to remove the serpentine belt to replace the belt itself.

Ads